The barite export business in Nigeria and Africa is a growing industry driven by the high demand for barite, a key mineral used in oil and gas drilling, as well as other industrial applications. Barite (BaSO₄) is primarily used as a weighting agent in drilling fluids, which makes it indispensable to the global oil and gas sector. Nigeria holds a significant portion of Africa’s barite reserves, estimated at 15 million metric tons, primarily found in Benue, Nasarawa, Cross River, and Taraba states.

Globally, the barite market is projected to grow, driven by increasing oil exploration activities, with the global barite demand reaching about 9.9 million metric tons in 2022. Nigeria’s barite production, however, has yet to fully meet the demands of both local and international markets. There is a significant opportunity for barite exporters in Nigeria to tap into markets across Africa and beyond, where barite is still imported from other regions, such as China and India.

The barite export business in Nigeria and Africa offers substantial growth potential, with increased local production, investment in processing facilities, and adherence to international quality standards. By improving logistics, export policies, and exploring untapped reserves, Nigeria can significantly boost its share in the global barite trade, fostering economic growth and job creation. This mineral sector could play a crucial role in diversifying Nigeria’s economy, reducing its dependency on crude oil exports.

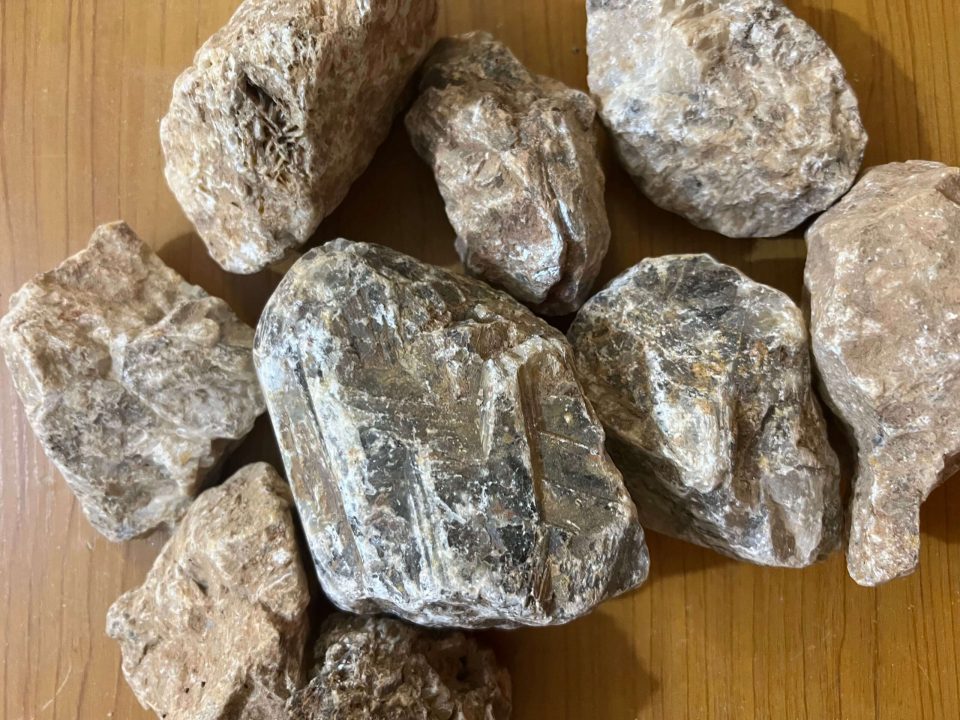

What Is Barite?

Barite, scientifically known as Barium Sulfate (BaSO₄), is a dense, non-metallic mineral used primarily in oil and gas drilling as a weighting agent for drilling fluids.

See Also: How To Start A Lucrative Barite Processing Business In Nigeria and Africa: The Complete Guide

What Is The Barite Export Business In Nigeria and Africa About?

The barite export business in Nigeria and Africa is a lucrative opportunity driven by the high demand for barite, a key mineral used extensively in the oil and gas industry as a weighting agent in drilling fluids. Nigeria and Africa possess significant barite reserves, making the region a viable source for local and international markets. Nigeria alone is estimated to have over 15 million metric tons of barite reserves, with large deposits found in states like Benue, Nasarawa, and Cross River. Despite the abundance, local production is still insufficient to meet market demand, leading to reliance on imports.

With rising global demand, the barite export business in Nigeria and Africa presents a huge opportunity for entrepreneurs to invest in barite mining, processing, and export. By improving production capacity, adhering to international standards, and targeting global markets, businesses can unlock substantial growth and profitability in this industry.

See Also: How To Start A Lucrative Barite Mining Business In Nigeria and Africa: The Complete Guide

Uses of Barite Around The World

1. Oil and Gas Drilling:

One of the primary uses of barite globally is in oil and gas drilling. Barite is added to drilling fluids as a weighting agent to control high pressure in deep wells and prevent blowouts. This usage drives a significant portion of the global demand, especially in regions like the Middle East, North America, and Russia. The barite export business in Nigeria and Africa benefits greatly from supplying barite to these oil-rich regions.

2. Paints and Coatings:

Barite is widely used as a filler in the paints and coatings industry. Its high specific gravity and whiteness make it ideal for producing high-quality paints. Barite improves the consistency, durability, and aesthetic quality of paints, making it a key material in industries across Europe, Asia, and North America.

3. Medical Industry:

Barite is used in the medical field as a contrast agent for X-ray and CT imaging. Barium sulfate, derived from barite, is ingested or administered to highlight areas of the digestive system, making it an important tool in diagnostic imaging. This medical application contributes to the global demand for barite.

4. Rubber and Plastics:

In the rubber and plastics industries, barite is used as a filler material. It enhances the durability and performance of rubber and plastic products by increasing strength and resistance to wear. Barite’s use in these industries creates a steady demand across sectors, especially in automotive and construction.

5. Glass Manufacturing:

Barite is used in glass production to improve clarity and prevent bubble formation. It ensures higher quality glass by enhancing its strength and reducing imperfections. This application is crucial in construction and consumer goods, contributing to the barite export business in Nigeria and Africa.

6. Chemical Industry:

Barite is used in the chemical industry to manufacture barium-based chemicals. These chemicals are used in various industrial processes, including the production of lubricants, pigments, and other barite derivatives. This application supports consistent demand from global chemical industries.

7. Paper Production:

Barite acts as a pigment and filler in paper production, improving the brightness and opacity of paper. It helps in producing high-quality printing paper, widely used in the publishing and advertising sectors around the world, contributing to the demand for barite in the global market.

8. Radiation Shielding:

Barite’s high density makes it ideal for use in radiation shielding materials. It is used in hospitals, nuclear facilities, and laboratories to shield against harmful radiation, adding another dimension to its applications globally.

9. Friction Products:

Barite is used in manufacturing friction products like brake pads and clutches in the automotive industry. It enhances the strength and durability of these products, ensuring their effectiveness under high-stress conditions. This application creates consistent demand in the global automotive industry.

10. Ceramics:

Barite is used in the ceramics industry as a flux, which lowers the melting point of ceramic materials. It improves the strength and quality of the final ceramic products, widely used in industrial and household applications.

11. Cosmetics:

Barite is used in cosmetic products such as face powders and foundations. It improves the texture and opacity of these products, providing a smooth application. The cosmetics industry globally relies on barite for this purpose, contributing to steady demand.

12. Pharmaceutical Industry:

Barite is used in the pharmaceutical industry, especially in the production of barium meals used for medical imaging. Its purity and non-toxic nature make it suitable for ingestion in medical tests, creating global demand from the healthcare sector.

13. Adhesives and Sealants:

In the construction and automotive industries, barite is used in adhesives and sealants to enhance their strength and stability. This application is crucial in producing high-performance materials that can withstand harsh conditions, leading to consistent demand for barite.

14. Fire Extinguishers:

Barite is also used in fire-extinguishing materials for its flame-retardant properties. It plays a critical role in preventing and controlling fires in industrial settings, further expanding its global applications.

15. Fertilizers:

Barite is used in agriculture as an additive in fertilizers, helping to enhance soil nutrients. This application is particularly relevant in regions where soil enrichment is essential for crop productivity, adding value to the barite export business in Nigeria and Africa.

16. Textile Industry:

Barite is used in the production of finishes for textiles, improving the durability and appearance of fabrics. This application is relevant in regions with large textile manufacturing industries, such as Asia and Africa.

17. Electrical Insulation:

Barite is used in electrical insulators due to its high dielectric properties. These insulators are essential in high-voltage electrical systems, driving global demand in the energy and power generation industries.

18. Ink Production:

In the printing industry, barite is used as a pigment to improve the brightness and opacity of ink. This application supports the production of high-quality printed materials used in advertising, packaging, and publishing.

19. Explosives:

Barite is used as a filler in the production of explosives, contributing to their stability and effectiveness. This application is particularly important in the mining and construction sectors, creating a consistent demand for barite globally.

20. Metallurgy:

In metallurgy, barite is used to remove impurities during the refining of metals. It plays a vital role in producing high-quality metals for various industrial applications, supporting global demand for processed barite.

21. Soundproofing Materials:

Barite’s density makes it ideal for use in soundproofing materials. These materials are used in buildings, vehicles, and other settings where noise reduction is critical, particularly in urban areas with high noise pollution levels.

22. Pesticides:

Barite is used in the production of pesticides and herbicides that are essential for crop protection in agriculture. This application supports the agricultural industry, especially in developing regions where food production is a priority.

23. Hydraulic Fracturing:

Barite is used in hydraulic fracturing (fracking) for oil and gas extraction. It helps maintain pressure and control fluid flow in wells, making it a crucial material in energy exploration worldwide.

24. Soil Stabilization:

In construction, barite is used to stabilize soil, improving its load-bearing capacity. This application is important in areas with weak soils, supporting infrastructure development and construction projects globally.

25. Water Treatment:

Barite is used in water treatment processes to remove impurities and contaminants. This application ensures the safe use of water for industrial and human consumption, particularly in regions facing water scarcity and contamination issues.

Benefits of The Barite Export Business In Nigeria and Africa

- Revenue Generation: The barite export business in Nigeria and Africa contributes significantly to national revenue. By exporting barite, countries can generate foreign exchange earnings, which can be reinvested in local economies and infrastructure development. This revenue stream is particularly crucial for developing nations seeking to diversify their economies and reduce dependency on traditional sectors.

- Job Creation: Engaging in the barite export business creates a multitude of job opportunities, from mining and processing to logistics and sales. This job creation can help alleviate poverty and improve living standards for local communities. Moreover, it encourages the development of skills and expertise in the workforce, fostering a more knowledgeable and capable labor pool.

- Economic Diversification: The barite export business helps diversify the economy by reducing reliance on oil and gas revenues, which can be volatile. By investing in the mining and processing of barite, countries can develop a more balanced economy, which is less susceptible to global market fluctuations. This diversification can lead to more sustainable economic growth over time.

- Infrastructure Development: Investment in the barite export business often necessitates improvements in infrastructure, such as roads, ports, and processing facilities. These enhancements benefit not only the barite industry but also other sectors by improving transportation and access to markets. Improved infrastructure can attract further investment, enhancing overall economic development.

- Technology Transfer: The barite export business encourages the introduction of advanced mining and processing technologies. As companies seek to enhance efficiency and product quality, they often bring in new technologies and techniques. This transfer of knowledge and skills can benefit local industries and improve overall productivity in the region.

- Increased Investment: The potential for profitability in the barite export business attracts both local and foreign investments. Investors are often keen to capitalize on the rich barite deposits in Nigeria and Africa. Increased investment not only boosts the barite sector but also stimulates growth in related industries, fostering economic resilience.

- Enhanced Trade Relations: Engaging in the barite export business fosters trade relationships between Nigeria, Africa, and other countries. These relationships can lead to trade agreements and partnerships that benefit multiple sectors of the economy. Strong trade ties can enhance diplomatic relations and encourage cultural exchange.

- Support for Local Businesses: The barite export business can stimulate demand for local suppliers and service providers, such as equipment manufacturers, transport companies, and construction firms. This creates a multiplier effect within the economy, supporting a range of local businesses and contributing to overall economic growth.

- Environmental Management: With proper regulation, the barite export business can promote sustainable mining practices that protect the environment. As countries become more aware of the importance of environmental sustainability, the barite industry can lead the way in implementing eco-friendly practices, setting a standard for other sectors.

- Skill Development: The barite export business provides opportunities for training and skill development. Workers in the sector can gain valuable skills in mining, processing, logistics, and quality control. These skills not only benefit individuals but also enhance the overall human capital of the region.

- Contribution to GDP: The barite export business contributes to the Gross Domestic Product (GDP) of Nigeria and African nations. As the industry grows, it boosts overall economic performance, leading to higher living standards and increased public services funded by tax revenues from the sector.

- Export Diversification: Engaging in the barite export business helps diversify export portfolios, reducing reliance on a limited range of commodities. By adding barite to the list of exported goods, countries can achieve greater stability in their trade balances and mitigate risks associated with commodity price fluctuations.

- Development of Support Services: The barite export business creates a demand for various support services, including research and development, marketing, and regulatory compliance. These services not only support the barite industry but also lead to the growth of related sectors, fostering a more robust economy.

- Market Expansion: The global demand for barite presents an opportunity for Nigeria and Africa to expand their markets. By tapping into international markets, the barite export business can open new avenues for revenue generation and enhance the region’s visibility in the global arena.

- Strengthening Local Communities: The barite export business can have a positive impact on local communities by providing funding for community development projects. This includes investments in education, healthcare, and infrastructure, contributing to the overall well-being of the population and fostering a sense of community pride.

− Export Business −

Make Your First $25,000 Exporting Products From Nigeria WITHOUT SPENDING YOUR OWN MONEY!

Our in-depth online export course is specifically designed to help you build a successful export business from scratch IN 90 DAYS WITHOUT LOSING MONEY FROM YOUR INVESTMENTS OR SPENDING YOUR OWN MONEY! And in the process, show you how to MAKE YOUR FIRST $25,000 from the export business within the first 3 months of finishing the course.

Click Here To Learn More >>

Business Opportunities In The Barite Export Business In Nigeria and Africa

- Mining Operations:

The foundation of the barite export business begins with mining. Companies can invest in the exploration and extraction of barite deposits. Nigeria is rich in natural resources, and setting up mining operations can yield substantial returns, especially when focused on sustainable practices and compliance with regulatory standards. - Processing Facilities:

Establishing processing plants to refine barite can add significant value to the raw material. Processing includes crushing, grinding, and bagging, which prepares barite for export. This business opportunity allows for higher profit margins compared to selling raw barite alone, as processed barite meets specific customer needs. - Export Logistics and Freight Services:

The logistics of exporting barite, including transportation and customs handling, presents a viable business opportunity. Companies can specialize in freight services, ensuring efficient and cost-effective transportation of barite from processing facilities to international markets, facilitating smoother trade operations. - Quality Control and Testing Services:

With the increasing demand for high-quality barite, businesses focused on quality control and testing can thrive. Establishing laboratories to test barite samples for purity and compliance with international standards can enhance the credibility of exporters and ensure customer satisfaction. - Packaging Solutions:

Investing in packaging solutions tailored for barite can improve the marketability and handling of the product. Companies can develop durable, branded packaging that protects barite during transport, which can also serve as a marketing tool to attract buyers. - Consultancy Services:

As the barite export business expands, consultancy services in areas like compliance, regulatory requirements, and market analysis will be essential. Firms offering expert advice on navigating the complexities of the export process can support local businesses in optimizing their operations. - Research and Development:

Investing in R&D to develop new applications for barite can open additional markets. Researching how barite can be used in various industries, such as pharmaceuticals, agriculture, and cosmetics, can lead to innovative products and increased demand. - Local Supplier Networks:

Creating a network of local suppliers for raw materials and services necessary for the barite export business is another opportunity. Establishing relationships with local vendors can help streamline operations and ensure a steady supply of quality inputs for processing and export. - Market Expansion Strategies:

Companies can explore international markets where barite demand is high, such as the United States and Europe. Developing marketing strategies to target specific industries, such as oil and gas or construction, can help in expanding the customer base and boosting sales. - Training and Workforce Development:

As the barite export business grows, so does the need for skilled labor. Establishing training programs that equip workers with the necessary skills for mining, processing, and logistics can create a competitive workforce, enhancing overall productivity. - Sustainable Mining Practices:

Promoting sustainable mining practices can lead to business opportunities focused on environmentally friendly operations. Companies that adopt and promote green practices may attract partnerships and funding from international organizations and environmentally conscious consumers. - International Trade Partnerships:

Forming partnerships with international buyers can create lucrative opportunities for exporting barite. Building strong relationships with foreign distributors and wholesalers can ensure consistent demand and stability in sales. - Barite Product Diversification:

Exploring the production of barite-based products, such as paint additives or drilling muds, can diversify the business. This diversification not only reduces risk but also taps into various markets, increasing revenue potential. - Government and NGO Collaborations:

Partnering with government agencies and NGOs focused on mineral development can provide access to funding and resources. These collaborations can also enhance credibility and provide networking opportunities within the industry. - Trade Shows and Industry Events:

Participating in trade shows and industry events focused on mining and minerals can increase visibility and create networking opportunities. Businesses can showcase their products, connect with potential clients, and learn about the latest trends in the barite export market.

Facts About The Barite Export Business In Nigeria and Africa

- Mineral Composition: Barite is primarily composed of barium sulfate (BaSO₄) and is known for its high density, which makes it invaluable in various industrial applications.

- Global Reserves: Nigeria is among the top 10 countries globally with substantial barite reserves, estimated at over 41 million metric tons.

- Oil and Gas Industry: Approximately 80% of barite produced globally is used in the oil and gas industry as a weighting agent in drilling fluids, ensuring well stability.

- Market Value: The global barite market was valued at approximately $3 billion in 2021, with expected growth driven by rising demand from oil and gas exploration.

- Export Opportunities: Nigeria’s strategic location and high-quality barite present significant export opportunities to countries such as the United States, China, and India.

- Local Processing: Investing in local barite processing facilities can enhance the mineral’s value, increasing the profitability of exports by up to 30%.

- Regulatory Framework: The Nigerian government has established mining regulations to promote sustainable practices and protect the environment while boosting the barite industry.

- Job Creation: The barite industry provides thousands of jobs across Nigeria, supporting local economies and reducing unemployment rates.

- Environmental Standards: Implementing environmentally friendly mining practices helps mitigate adverse effects, ensuring the longevity of barite resources.

- Research Initiatives: Universities and research institutions in Nigeria are conducting studies to explore new applications for barite, including its use in pharmaceuticals and cosmetics.

- Logistics Infrastructure: Improved transportation infrastructure, such as roads and ports, is critical for enhancing the efficiency of barite export operations.

- Quality Control: Strict adherence to international quality standards is essential for barite exports, as buyers demand high purity and low impurities.

- Investment Growth: Increased foreign direct investment (FDI) in Nigeria’s mining sector is fostering growth in the barite export business.

- Regional Demand: Countries in West Africa, such as Ghana and Senegal, are emerging markets for Nigerian barite, driven by local mining activities.

- Technology Adoption: Incorporating modern technologies, such as automated processing and data analytics, can optimize production efficiency and reduce costs.

- Export Licensing: Obtaining export licenses and certifications can streamline the export process and ensure compliance with international trade regulations.

- Bargaining Power: Nigerian exporters have favorable bargaining positions due to the country’s high-quality barite compared to lower-quality imports.

- Diverse Applications: Beyond oil and gas, barite is also used in the production of paints, rubber, and plastics, showcasing its versatility.

- Partnership Opportunities: Forming strategic alliances with global companies can facilitate knowledge transfer and improve market access for Nigerian barite.

- Market Trends: The increasing emphasis on renewable energy sources and eco-friendly drilling practices is influencing the demand for high-purity barite.

- Community Engagement: Engaging local communities in barite mining operations promotes social responsibility and builds goodwill, which can lead to smoother operations.

- Sustainability Practices: Implementing sustainable mining techniques, such as reclamation and biodiversity conservation, enhances the industry’s reputation.

- Trade Agreements: Bilateral trade agreements between Nigeria and key markets can facilitate smoother trade and reduce export tariffs on barite.

- Educational Programs: Providing training programs focused on best practices in mining and processing can improve workforce capabilities and operational standards.

- Future Prospects: With continued investment and innovation, the barite export business in nigeria and africa is poised for significant growth, contributing to economic diversification.

Types Of Barite Export Businesses In Nigeria and Africa

- Raw Barite Exporters: These businesses focus on sourcing and exporting unprocessed barite directly from mines to international markets. They typically negotiate contracts with mining companies to secure high-quality barite, which is then transported to ports for export. The raw form is particularly in demand for industries that process barite for various applications.

- Processed Barite Exporters: Companies in this category specialize in refining and processing barite to meet specific industry standards before export. This can include milling, pulverizing, and packaging barite into different grades. Processed barite commands a higher price on the international market, as it is ready for immediate use in applications like oil drilling.

- Barite Supply Chain Management Firms: These businesses focus on the entire logistics and supply chain for barite, from sourcing raw materials to delivering processed products to clients abroad. They manage the transportation, customs clearance, and storage of barite, ensuring timely delivery and compliance with international regulations.

- Barite Trading Companies: These firms act as intermediaries between barite producers and international buyers. They often have established relationships with both mining companies and end-users, allowing them to negotiate better prices and ensure consistent supply. Trading companies may also deal with various forms of barite, including raw and processed.

- Export Agents and Brokers: These individuals or companies facilitate barite transactions by connecting sellers and buyers. They may provide services such as market research, negotiation, and logistics management. While they don’t usually handle the physical products, their expertise in export regulations and market trends can significantly benefit barite export businesses.

- Barite Distribution Companies: Focused on the distribution aspect, these companies purchase barite in bulk and sell it to smaller buyers or retailers in foreign markets. They often have established networks for distribution and logistics, making it easier for smaller clients to access barite without the need for direct importing.

- Joint Venture Enterprises: In this model, local Nigerian companies collaborate with foreign firms to exploit and export barite resources. Joint ventures can help leverage the technical expertise and market access of international partners while providing local firms with the necessary capital and knowledge to compete globally.

- Niche Market Exporters: Some businesses focus on specific applications of barite, such as pharmaceuticals or specialty chemicals. By targeting niche markets, these exporters can achieve higher margins and establish a loyal customer base, even if their volume of exports is lower compared to mainstream markets.

- Barite Quality Control Specialists: These companies focus on ensuring that barite meets international quality standards. They may provide testing and certification services for barite products, adding value to the export process by assuring buyers of the material’s quality and suitability for specific applications.

- Research and Development Firms: These enterprises focus on developing new uses for barite or improving processing techniques. They may work closely with manufacturers to explore innovative applications of barite in various industries, thereby creating additional demand and export opportunities.

Types Of Barite That Can Be Exported From Nigeria and Africa

- High-Grade Barite: This type of barite is characterized by a high barium sulfate content of over 90%. It is primarily used in the oil and gas industry as a drilling mud additive. The high density of high-grade barite stabilizes boreholes during drilling operations, preventing blowouts, which is critical for safety and efficiency. There is a strong demand for this type of barite in both domestic and international markets, making it a valuable product for export.

- Low-Grade Barite: Low-grade barite contains less than 90% barium sulfate and is typically used in less demanding applications. These can include construction as a filler material and as a weighting agent in certain industrial products. Despite being less valuable than high-grade barite, there are niche markets where low-grade barite can still find opportunities for sale.

- Chemical Grade Barite: This type is specifically processed to meet certain chemical purity standards, making it suitable for various chemical applications such as paints, plastics, and rubber. The high purity levels achieved through advanced processing techniques enhance its marketability. As industries increasingly seek quality materials, the export potential for chemical-grade barite is growing.

- API Grade Barite: API grade barite conforms to the specifications set by the American Petroleum Institute (API), ensuring sufficient quality for drilling fluids. This barite is specifically treated and tested to meet stringent industry standards, which makes it highly sought after in the oil and gas sector. There is a robust export market for API-grade barite among oil and gas companies.

- Industrial Grade Barite: Industrial-grade barite is used in manufacturing processes for products like glass and ceramics. This type requires specific particle size distributions tailored to the needs of various industries. Its versatility allows it to be exported to diverse markets, thus expanding business opportunities.

- Barite Ore: Barite ore refers to the raw, unprocessed form mined directly from the ground. It serves as the starting material for processing into higher-grade products. Understanding the properties of barite ore is essential for determining processing requirements and identifying potential markets.

- Coated Barite: Coated barite features particles coated with a thin layer of another material, enhancing properties such as water resistance or flow characteristics. The niche market for coated barite is expanding, offering unique opportunities for exporters to cater to specific industry needs.

- Microfine Barite: This type is processed to achieve very small particle sizes, often below 10 microns. Microfine barite is useful in applications requiring a high surface area, such as pharmaceuticals and specialty paints. The growing demand for microfine barite presents lucrative segments for exporters to tap into.

- Barite for Radiological Shielding: This type of barite is specifically used in applications requiring radiation shielding, such as hospitals and nuclear facilities. It has specific density requirements to effectively block radiation, creating a niche market with significant potential for barite exports.

- Barite for Agriculture: Although less common, barite can also be used as a soil amendment to improve soil properties. This application reflects the versatility of barite, and it opens new markets for the barite export business in Nigeria and Africa.

The Peak Season For The Barite Export Business In Nigeria and Africa

The peak production, supply, and demand season for the barite export business in Nigeria and Africa generally aligns with the dry season, which typically runs from November to March. During this period, mining operations are most efficient due to favorable weather conditions, minimizing disruptions caused by rain. Consequently, production rates tend to be at their highest, allowing exporters to meet the increased demand from international markets.

Demand for barite peaks during this same period, particularly from the oil and gas sector, as companies ramp up drilling activities in anticipation of higher production during the subsequent wet season. Additionally, construction activities often surge, as many infrastructure projects are initiated before the rains. Export opportunities are particularly pronounced during these months, as global demand for barite increases to support drilling fluids and other applications. Overall, understanding these seasonal trends is crucial for stakeholders in the barite export business in Nigeria and Africa.

How To Start The Barite Export Business In Nigeria and Africa: Step-By-Step Guide

- Conduct Market Research: Before starting the barite export business, it is crucial to conduct thorough market research. This involves understanding the demand for barite in different countries, identifying potential buyers, and analyzing the competition. Gathering data on price trends, quality specifications, and market requirements will help you tailor your offerings to meet customer needs.

- Develop a Business Plan: A well-structured business plan is essential for guiding your barite export venture. This document should outline your business goals, target market, marketing strategy, operational plan, financial projections, and funding requirements. A solid business plan not only serves as a roadmap for your business but is also crucial for attracting investors or securing loans.

- Obtain Necessary Licenses and Permits: Starting a barite export business requires compliance with various regulations. You must obtain the necessary licenses and permits from local and national authorities. This may include mining permits, export licenses, and environmental clearances. Ensure that you are aware of the legal requirements specific to your region.

- Source Quality Barite: Identify reliable suppliers or mining sites that produce high-quality barite. The quality of barite is critical for meeting international standards and satisfying customer specifications. Establishing relationships with local miners or exploring potential mining sites can help secure a consistent supply of quality material.

- Establish Logistics and Supply Chain: Efficient logistics are vital for the successful export of barite. This includes selecting transportation methods, arranging for storage facilities, and ensuring that your products are packaged appropriately for export. Collaborate with freight forwarders to navigate customs and shipping processes, ensuring timely delivery to international markets.

- Build a Network of Buyers: Developing a strong network of potential buyers is essential for sustaining your export business. Attend trade shows, industry conferences, and networking events to connect with potential clients in the oil and gas, construction, and drilling industries. Utilizing digital platforms and social media can also help you reach a broader audience.

- Implement Quality Control Measures: Establishing quality control measures is crucial for maintaining the standards of your barite. Regular testing and monitoring of your product will ensure consistency in quality, which is essential for repeat business. Consider obtaining certifications that validate the quality of your barite, as this can enhance your marketability.

- Market Your Barite: Create a marketing strategy to promote your barite export business. This can include online marketing, participation in industry exhibitions, and direct outreach to potential clients. Highlight the unique selling points of your barite, such as quality, pricing, and availability, to attract buyers.

- Monitor and Adapt: Once your barite export business is operational, continuously monitor market trends, customer feedback, and operational efficiency. Be prepared to adapt your strategies based on changing market conditions, competition, and customer demands. Regularly reviewing your business performance will help you identify areas for improvement.

- Expand Your Business: After establishing a successful barite export operation, consider exploring opportunities for growth. This could involve expanding your product range, entering new markets, or enhancing your operational capabilities. Diversification can help mitigate risks and increase your revenue streams in the long run.

How To Source Barite For Export In Nigeria and Africa

- Identify Potential Suppliers: Start by researching potential suppliers of barite in Nigeria and Africa. This includes local mining companies, small-scale miners, and processing plants. Utilize online directories, trade associations, and industry reports to compile a list of reputable suppliers. Networking at industry events or trade shows can also provide valuable contacts.

- Evaluate Quality Standards: Ensure that the barite sourced meets international quality standards. This can be done by requesting samples from potential suppliers and conducting laboratory tests to analyze purity, density, and particle size distribution. Familiarize yourself with the specific requirements of your target markets, as different industries (e.g., oil and gas, construction) may have varying standards.

- Conduct Site Visits: Whenever possible, visit the suppliers’ mining sites and processing facilities. This will give you a firsthand understanding of their operations, production capacity, and quality control measures. On-site evaluations also help build trust and rapport with suppliers, making it easier to negotiate favorable terms.

- Negotiate Supply Agreements: Once you have identified reliable suppliers, negotiate supply agreements that outline pricing, payment terms, delivery schedules, and quality specifications. It’s important to establish clear communication and mutual understanding to avoid potential disputes in the future. Consider including clauses for penalties or incentives based on performance metrics.

- Assess Logistics and Transportation: Evaluate the logistics involved in transporting barite from the supplier to your processing facility or directly to export destinations. Determine the most cost-effective and efficient transportation methods, whether by road, rail, or sea. Work with logistics partners who have experience in handling bulk materials to ensure timely and safe delivery.

- Establish Quality Control Procedures: Implement quality control procedures to ensure that the barite received meets the required specifications. This includes routine inspections and testing of incoming shipments. Having a quality assurance team or collaborating with third-party inspectors can help maintain consistency and avoid costly rejections from buyers.

- Maintain Regulatory Compliance: Familiarize yourself with the legal and regulatory requirements related to sourcing and exporting barite in Nigeria and Africa. This includes obtaining the necessary licenses and permits, adhering to environmental regulations, and ensuring compliance with international export laws. Engage with local authorities and export promotion agencies for guidance.

- Build Strong Supplier Relationships: Cultivating strong relationships with your suppliers is crucial for the long-term success of your sourcing efforts. Regular communication, transparency, and mutual support can lead to better pricing, priority access during peak seasons, and favorable terms in future negotiations. Consider establishing long-term contracts to secure consistent supply.

- Diversify Your Sourcing Options: Avoid relying on a single supplier to mitigate risks associated with supply disruptions. Explore multiple sourcing options across different regions in Nigeria and Africa. This diversification not only provides backup sources but also allows you to compare prices and quality across different suppliers.

- Monitor Market Trends: Stay updated on market trends, pricing fluctuations, and changes in demand for barite. This knowledge will help you make informed sourcing decisions and adapt your strategies accordingly. Engaging in market research and subscribing to industry publications can provide valuable insights that inform your sourcing approach.

How To Ensure International Quality Standards Are Met For Barite Export From Nigeria and Africa

- Understand the Required Standards: Before beginning your barite export business in Nigeria and Africa, familiarize yourself with the international quality standards applicable to barite. This includes specifications from organizations such as ASTM International and API (American Petroleum Institute). Knowing the required parameters for purity, density, moisture content, and particle size is crucial for compliance.

- Conduct Comprehensive Market Research: Perform thorough market research to understand the expectations of your target markets regarding barite quality. Analyze the quality requirements for specific industries, such as oil and gas, construction, and pharmaceuticals. Engaging with end-users or industry professionals can provide valuable insights into their quality standards and preferences.

- Source High-Quality Raw Materials: Ensure that the barite you source is of high quality from the outset. Collaborate with reputable suppliers who can provide barite that meets or exceeds international quality specifications. This may involve conducting site visits, requesting samples, and performing quality checks on raw materials before procurement.

- Implement Quality Control Procedures: Establish robust quality control measures throughout the sourcing, processing, and export stages. This includes regular inspections, laboratory testing, and monitoring of quality parameters. Document all quality checks and test results to create a transparent quality assurance system that can be presented to customers and regulators.

- Invest in Modern Processing Equipment: Upgrading your processing facilities with modern equipment can significantly improve the quality of barite produced. Advanced machinery can enhance sorting, grinding, and packaging processes, ensuring that the final product meets international quality standards. Additionally, consider automation where possible to minimize human error and maintain consistency.

- Train Your Workforce: Equip your workforce with the necessary skills and knowledge to adhere to quality standards. Conduct regular training sessions on best practices for processing, handling, and quality assessment. This ensures that all employees are aware of their roles in maintaining product quality and can contribute effectively to quality assurance efforts.

- Adopt Good Manufacturing Practices (GMP): Implement Good Manufacturing Practices in your processing operations to enhance product quality. This involves standardizing procedures for equipment cleaning, maintenance, and operation. Regular audits and inspections of your facility can help ensure compliance with GMP guidelines and identify areas for improvement.

- Collaborate with Third-Party Quality Assurance Agencies: Engaging third-party quality assurance agencies can provide an unbiased evaluation of your barite quality. These agencies can conduct independent testing and certification, verifying that your product meets international standards. Having a recognized certification can enhance your credibility and reassure customers of your commitment to quality.

- Maintain Detailed Records: Keep comprehensive records of all quality checks, testing results, supplier certifications, and process improvements. Detailed documentation not only helps in maintaining standards but also provides evidence of compliance during audits or inspections. This transparency builds trust with customers and regulatory bodies.

- Continuously Monitor and Improve Quality: Quality assurance is an ongoing process that requires continuous monitoring and improvement. Regularly review your quality management system to identify weaknesses and areas for enhancement. Gather feedback from customers and stakeholders to refine your processes and ensure that your barite export business remains competitive in the international market.

Types Of Barite Export Incoterms In Nigeria and Africa

- EXW (Ex Works): EXW places the maximum responsibility on the buyer, meaning the seller’s only obligation is to make the goods available at their premises. For the barite export business in Nigeria and Africa, this means that buyers need to arrange for all transportation, customs clearance, and handling of the barite from the seller’s location. While this term is beneficial for sellers due to limited responsibility, it may increase costs and complexities for buyers unfamiliar with logistics.

- FCA (Free Carrier): Under FCA, the seller delivers the barite to a specified carrier or location, and the risk transfers to the buyer once the goods are handed over. This term is suitable for the barite export business in Nigeria and Africa, allowing sellers to manage the initial transportation phase while giving buyers more control over further transportation and logistics. The seller is responsible for clearing the goods for export, ensuring compliance with regulations.

- CPT (Carriage Paid To): In this arrangement, the seller pays for the transportation of the barite to a designated location, transferring the risk to the buyer once the goods are handed over to the carrier. This term is advantageous for buyers as they have clarity on transportation costs. For the barite export business in Nigeria and Africa, CPT helps streamline logistics and simplifies budgeting for buyers, as the seller covers the initial shipping expenses.

- CIP (Carriage and Insurance Paid To): CIP is similar to CPT but includes insurance coverage for the goods during transit. The seller is responsible for paying transportation and insurance costs until the barite reaches the specified destination. This term is particularly beneficial in the barite export business in Nigeria and Africa, as it provides an additional layer of security for buyers, protecting their investment against potential losses during transportation.

- DAP (Delivered at Place): DAP requires the seller to deliver the barite to a specified location, bearing all costs and risks until the goods arrive. This term places a higher level of responsibility on the seller compared to earlier terms, making it easier for buyers as they do not have to worry about transport logistics. For the barite export business in Nigeria and Africa, DAP is an attractive option for buyers seeking a hassle-free purchasing experience.

- DPU (Delivered at Place Unloaded): DPU is a relatively new term in the Incoterms 2020. It requires the seller to deliver the barite to a specified location and unload it there. This term significantly reduces the buyer’s responsibility, making it beneficial in regions where offloading capabilities are limited. In the context of the barite export business in Nigeria and Africa, DPU can enhance the overall customer experience by ensuring that the goods are delivered and offloaded at the buyer’s premises.

- DDP (Delivered Duty Paid): DDP places the maximum responsibility on the seller, who must deliver the barite to the buyer’s location, including payment of all duties and taxes. This term is beneficial for buyers in the barite export business in Nigeria and Africa, as it simplifies the import process. Buyers receive the goods ready for use, with all logistics and customs formalities handled by the seller, making it a highly attractive option.

- FAS (Free Alongside Ship): Under FAS, the seller delivers the barite alongside the vessel designated by the buyer. The risk transfers to the buyer once the goods are placed alongside the ship. This term is primarily used for sea transport and requires sellers to ensure the barite reaches the port and is in the right condition for loading. It allows buyers to handle the shipping process from that point, making it suitable for the barite export business in Nigeria and Africa.

- FOB (Free on Board): FOB requires the seller to load the barite onto the vessel chosen by the buyer at the port of shipment. The risk is transferred to the buyer once the goods are on board. This term is widely used in international trade, including the barite export business in Nigeria and Africa. FOB is favorable for buyers who wish to control their shipping arrangements while ensuring that sellers bear the costs and responsibilities until loading.

- CFR (Cost and Freight): Under CFR, the seller pays for the costs and freight necessary to bring the barite to the port of destination, while the risk transfers to the buyer once the goods are on board. This term allows sellers to cover initial shipping costs while providing buyers the freedom to manage insurance and other expenses once the goods are shipped. It is a practical option for the barite export business in Nigeria and Africa, allowing for a balanced sharing of responsibilities.

- CIF (Cost, Insurance, and Freight): CIF includes transportation costs, insurance, and freight charges. The seller is responsible for costs up to the destination port, and the risk transfers to the buyer once the goods are loaded on the ship. CIF is particularly appealing in the barite export business in Nigeria and Africa, as it provides buyers with cost coverage and protection against potential losses during transport.

How To Manage Logistics For The Barite Export Business In Nigeria and Africa

- Understanding the Supply Chain: To effectively manage logistics in the barite export business in Nigeria and Africa, it is crucial to understand the entire supply chain. This involves mapping out the journey from the extraction of barite from mines to its delivery at the destination port. Identifying key players in the supply chain—such as suppliers, transportation companies, and customs authorities—will facilitate smoother operations. A well-defined supply chain can help in forecasting demand, managing inventory levels, and optimizing transportation costs.

- Selecting Reliable Transportation Partners: Choosing the right transportation partners is essential for the barite export business in Nigeria and Africa. Companies should evaluate potential logistics providers based on their reliability, experience in handling bulk materials, and ability to navigate the complexities of international shipping. Engaging with freight forwarders who specialize in mineral exports can help ensure compliance with regulations and facilitate timely deliveries. Establishing long-term partnerships with trusted logistics providers can also improve overall efficiency and reduce costs.

- Customs Clearance and Compliance: Navigating customs regulations is a critical aspect of logistics management for the barite export business in Nigeria and Africa. Exporters must be well-versed in the documentation and compliance requirements for both the exporting and importing countries. This includes obtaining necessary export permits, certificates of origin, and any other relevant paperwork. Working closely with customs brokers can expedite the clearance process, minimizing delays and avoiding penalties. Staying informed about changes in regulations can also prevent compliance issues.

- Inventory Management: Effective inventory management is vital in the barite export business to meet market demands without incurring excessive holding costs. Exporters should implement inventory control systems to track stock levels, monitor usage rates, and forecast demand based on market trends. Regular assessments of inventory turnover can help identify slow-moving products, allowing businesses to adjust their procurement strategies accordingly. Utilizing technology, such as inventory management software, can enhance accuracy and streamline operations.

- Implementing Quality Control Measures: Ensuring the quality of barite during the logistics process is essential for maintaining customer satisfaction and meeting international standards. Exporters should establish quality control measures at various stages, including sourcing, handling, and transportation. Regular inspections and testing of barite samples can help detect any inconsistencies or contaminants. By prioritizing quality throughout the supply chain, businesses can enhance their reputation and build trust with international buyers.

- Utilizing Technology and Tracking Systems: Leveraging technology in logistics management can greatly enhance efficiency and visibility in the barite export business in Nigeria and Africa. Implementing tracking systems enables exporters to monitor the movement of their shipments in real-time, providing transparency to both the company and its customers. Technologies such as GPS and RFID can improve route planning and optimize delivery schedules. Additionally, using transportation management software can aid in cost analysis and facilitate communication among stakeholders.

- Developing Contingency Plans: The unpredictability of logistics, especially in regions with infrastructure challenges, necessitates the development of contingency plans. Exporters should identify potential risks—such as transportation delays, equipment failures, or regulatory changes—and devise strategies to mitigate them. This might involve securing alternative transportation routes, maintaining relationships with multiple suppliers, or keeping a buffer stock of barite. Having well-defined contingency plans can ensure business continuity and minimize disruptions.

- Fostering Communication and Collaboration: Effective communication and collaboration among all stakeholders involved in the barite export process are critical for logistics success. Regular updates and open lines of communication with suppliers, logistics providers, and customers can help address issues proactively and foster a culture of teamwork. Utilizing collaborative platforms can enhance coordination and facilitate information sharing, enabling a more efficient logistics process.

- Cost Management and Optimization: Keeping logistics costs under control is essential for the profitability of the barite export business in Nigeria and Africa. Exporters should conduct regular cost analyses to identify areas for improvement, such as transportation expenses, warehousing fees, and customs duties. Exploring options for bulk shipping, negotiating rates with logistics providers, and optimizing delivery routes can lead to significant cost savings. Additionally, utilizing financial forecasting tools can assist in budgeting and planning for logistics expenses.

- Training and Development of Staff: Investing in the training and development of logistics staff is vital for ensuring operational efficiency in the barite export business. Employees should be well-informed about the intricacies of logistics management, including best practices for handling barite, compliance with regulations, and the use of technology. Providing ongoing training opportunities can enhance staff skills, improve job performance, and contribute to a more efficient logistics operation overall.

How To Package & Export Barite From Nigeria or Africa

- Understanding Barite Specifications: Before packaging barite for export, it’s essential to understand the specific requirements based on the target market. Different countries and industries have various standards for barite quality, including purity levels, particle size, and physical characteristics. Researching these specifications will help in ensuring that the packaged product meets international quality standards. This understanding can guide the selection of appropriate packaging materials and techniques that maintain barite quality during transit.

- Selecting Appropriate Packaging Materials: The choice of packaging materials plays a crucial role in the successful export of barite. Generally, barite is transported in bulk, but it can also be packaged in bags, drums, or containers, depending on customer requirements. High-quality, durable materials such as polypropylene bags, which are resistant to moisture and tearing, are commonly used for bagging barite. Additionally, using bulk containers with proper sealing can prevent contamination and maintain the integrity of the barite during transportation.

- Determining Packaging Sizes and Weight: When exporting barite, it’s important to determine the right packaging sizes and weight limits that align with shipping regulations and customer preferences. Common packaging sizes for barite include 1-ton bags or smaller 25-kg bags, which facilitate easier handling and transport. Understanding the weight restrictions set by shipping companies can help avoid additional costs and ensure compliance with international shipping standards.

- Labeling and Documentation: Proper labeling and documentation are essential for the smooth export of barite. Labels should clearly indicate the product name, weight, batch number, and any necessary handling instructions. Additionally, exporters must prepare the required shipping documents, including commercial invoices, packing lists, and certificates of origin. Accurate documentation ensures compliance with customs regulations in both the exporting and importing countries, preventing delays in the shipping process.

- Quality Control Measures: Implementing quality control measures is crucial in ensuring that the packaged barite meets the required standards. Before packaging, samples should be tested for quality parameters such as density, fineness, and purity. Regular inspections during the packaging process can help identify any inconsistencies or defects. By prioritizing quality control, exporters can enhance customer satisfaction and build trust with international buyers.

- Packaging Process: The actual packaging process should be carried out in a clean and controlled environment to avoid contamination. Barite should be handled with care to prevent breakage or damage to the packaging materials. Using automated or semi-automated packaging systems can improve efficiency and consistency in the packaging process. Once packaged, the bags or containers should be securely sealed to protect the barite from moisture and environmental factors during transit.

- Storage and Handling: After packaging, proper storage and handling of barite are critical to prevent deterioration of the product. Packaged barite should be stored in a dry, cool place, away from direct sunlight and moisture. Additionally, ensure that the storage area is well-organized to facilitate easy access and inventory management. Implementing proper handling practices during loading and unloading will help maintain the quality of the packaged barite and prevent spillage or damage.

- Shipping Arrangements: Once the barite is packaged and ready for export, shipping arrangements must be made. This involves selecting a reliable freight forwarder experienced in handling bulk mineral exports. The choice of transportation mode—whether by sea, land, or air—depends on factors such as cost, distance, and urgency. Working with reputable logistics companies ensures that the barite is transported safely and efficiently to its destination.

- Customs Clearance: Navigating customs regulations is an important step in the barite export business in Nigeria and Africa. Exporters must ensure that all necessary documents are prepared and submitted to customs authorities. This includes export permits, customs declarations, and any additional certificates required by the importing country. Properly handling customs clearance can prevent delays and potential fines, ensuring a smooth export process.

- Post-Export Follow-Up: After the barite has been exported, maintaining communication with the buyer is important. Following up on the delivery and addressing any concerns or feedback helps to strengthen business relationships. Gathering insights from the buyer about their satisfaction with the product can provide valuable information for future exports. Continuous improvement in packaging and export processes can enhance the overall efficiency and success of the barite export business.

See Also: Key Export Shipping Documents And The Organisations That Issue Them

Types Of Equipment & Tools Used In The Barite Export Business In Nigeria or Africa

- Crushers: Crushers are essential for breaking down barite ore into smaller pieces. They come in various types, including jaw crushers and impact crushers. The crushing process ensures that the barite is of a manageable size for further processing. Efficient crushers help in maximizing the yield and reducing the waste during the extraction process.

- Ball Mills: Ball mills are used for grinding crushed barite into fine powder. This equipment employs a rotating cylinder filled with balls to grind the material. The fine particle size achieved through milling is crucial for various applications, particularly in oil drilling and paint production.

- Air Classifiers: Air classifiers are used to separate particles based on their size and density. This equipment helps in obtaining a uniform particle size distribution, which is essential for meeting specific industry requirements. By ensuring consistent quality, air classifiers enhance the marketability of the final product.

- Vibrating Screens: Vibrating screens are employed to sort barite particles according to size. They help in removing oversized or undersized materials from the production line. Efficient screening is vital for ensuring the purity and quality of the barite being processed and packaged.

- Belt Conveyors: Belt conveyors are used to transport barite between different processing stages. They facilitate the smooth movement of materials, reducing manual handling and minimizing contamination risks. Efficient conveyor systems enhance productivity and streamline operations.

- Bagging Machines: Bagging machines automate the process of packaging barite into bags. These machines can fill, weigh, and seal bags efficiently, ensuring consistency and reducing labor costs. Bagging machines are crucial for preparing barite for shipment and ensuring that it meets customer specifications.

- Forklifts: Forklifts are essential for moving heavy bags of barite around the processing and storage facilities. They help in loading and unloading barite from trucks or shipping containers. Efficient use of forklifts enhances productivity and ensures safe handling of materials.

- Bulk Loaders: Bulk loaders are used to transfer large quantities of barite into shipping containers or trucks. They can handle both bulk bags and loose material, streamlining the loading process. Efficient bulk loading minimizes loading times and reduces labor costs.

- Mixers: Mixers are used to blend barite with other materials, such as additives for drilling fluids. They ensure that the mixture is homogeneous, which is crucial for achieving the desired properties of the final product. Proper mixing enhances the performance of barite in various applications.

- Dust Collectors: Dust collectors are essential for maintaining a clean working environment during the processing of barite. They capture airborne dust generated during crushing, grinding, and packaging operations. Effective dust control improves worker safety and complies with environmental regulations.

- Weighing Scales: Accurate weighing scales are necessary for measuring the quantity of barite during processing and packaging. They ensure that the correct amounts are loaded into bags or containers, helping to maintain product consistency and meet customer requirements.

- Quality Control Laboratory Equipment: Quality control equipment, including spectrometers and particle size analyzers, is used to test the quality of processed barite. These tools ensure that the barite meets industry standards and specifications before packaging and export.

- Cranes: Cranes are used for heavy lifting tasks, such as moving large bags of barite or equipment. They facilitate efficient loading and unloading operations in processing plants and export facilities. Proper crane operation enhances safety and reduces labor costs.

- Packaging Material Dispensers: These dispensers provide packaging materials, such as bags or containers, for the bagging process. Automated dispensers streamline operations by reducing manual handling and ensuring that the correct materials are used for packaging.

- Shipping Containers: Shipping containers are essential for transporting barite to international markets. They provide secure and weather-resistant storage during transit, protecting the barite from contamination and moisture. Proper containerization is crucial for maintaining product quality.

- Forklift Attachments: Various attachments for forklifts, such as clamps and pallet jacks, enhance the versatility of handling barite. These attachments allow for more efficient loading and unloading of different packaging types, improving operational efficiency.

- Water Spray Systems: Water spray systems are used for dust suppression during processing. They help reduce airborne dust particles, enhancing safety and compliance with environmental regulations. Maintaining a dust-free environment is essential for worker health and equipment longevity.

- Emergency Response Equipment: Safety equipment, such as fire extinguishers and first aid kits, is vital for ensuring a safe working environment in barite processing facilities. Regular inspections and maintenance of emergency response equipment are crucial for addressing potential hazards.

- Control Systems: Automated control systems monitor and manage the processing equipment. These systems ensure that operations run smoothly and efficiently, allowing for real-time adjustments based on production requirements. Enhanced automation leads to improved consistency and quality.

- Storage Silos: Storage silos are used for storing bulk barite before packaging and export. They protect the barite from moisture and contamination while allowing for easy access and inventory management. Efficient storage solutions are essential for optimizing space and managing inventory.

- Mobile Crushing Units: Mobile crushing units provide flexibility in processing barite directly at mining sites. These units can be easily transported and set up, reducing transportation costs and improving efficiency in operations.

- Environmental Monitoring Equipment: Environmental monitoring tools, such as air quality sensors and noise level meters, ensure compliance with environmental regulations during processing. These tools help operators maintain a sustainable and safe working environment.

- Automatic Labeling Machines: Automatic labeling machines streamline the process of labeling packaged barite. Proper labeling is crucial for providing customers with important information about the product, such as specifications and handling instructions.

- Sealing Machines: Sealing machines ensure that packaged barite is securely sealed to prevent contamination during transport. Proper sealing enhances the shelf life of the product and maintains its quality during export.

- Transport Trucks: Specialized transport trucks equipped for hauling bulk materials are essential for moving barite from processing facilities to export terminals. Reliable transportation is crucial for ensuring timely delivery to customers.

Target Market For The Barite Export Business In Nigeria or Africa

- Oil and Gas Companies: Oil and gas companies are among the primary consumers of barite, using it as a weighting agent in drilling fluids. The demand for barite in this sector is driven by exploration and production activities. Companies engaged in drilling operations require high-quality barite to maintain wellbore stability and ensure safety during drilling.

- Mining Companies: Mining companies utilize barite as a filler and weighting agent in various mineral extraction processes. They may also require barite for specific applications in mineral processing, making them significant customers in the barite export business. As mining operations expand, the demand for barite in this sector continues to grow.

- Construction Industry: In the construction industry, barite is often used as a component in concrete and cement products. Its density helps improve the strength and durability of construction materials. Builders and contractors seeking high-quality materials for construction projects are key customers for barite exporters.

- Paint Manufacturers: Paint manufacturers use barite as a pigment and filler in paint formulations. It provides opacity and improves the viscosity of paint products. With the continuous growth of the paint industry in Africa, paint manufacturers represent a valuable target market for barite.

- Plastic and Rubber Manufacturers: Barite is utilized as a filler in plastic and rubber products to enhance their properties. Manufacturers in these sectors seek barite to improve the quality and performance of their products. As the demand for plastic and rubber items rises, so does the potential for barite exports.

- Chemical Manufacturers: Chemical manufacturers require barite for various chemical processes, including the production of barium compounds. Barite’s properties make it suitable for applications in the chemical industry, where it serves as a crucial raw material. This sector presents a significant market opportunity for barite exporters.

- Ceramics and Glass Manufacturers: Ceramics and glass manufacturers use barite as a raw material to enhance the quality and durability of their products. Barite helps improve the melting process in glass production and adds strength to ceramic items. Targeting this market can be lucrative for barite exporters.

- Agricultural Sector: In agriculture, barite can be used in the formulation of fertilizers and soil amendments. It helps improve soil quality and nutrient retention. Companies producing agricultural products may be interested in sourcing barite to enhance their offerings, representing a niche market for exporters.

- Drilling Fluid Companies: Companies that specialize in manufacturing drilling fluids are direct consumers of barite. They require specific grades of barite to formulate high-performance drilling fluids for various applications. Partnering with these companies can lead to long-term business relationships in the barite export business.

- Environmental Agencies: Environmental agencies and organizations may require barite for soil remediation and stabilization projects. Barite’s properties can help mitigate environmental issues, making these agencies potential customers for barite exporters focused on sustainable practices.

- Pharmaceutical Companies: Some pharmaceutical companies use barium sulfate (derived from barite) in medical imaging and diagnostic procedures. They may seek high-purity barite for their applications, presenting a specialized market opportunity for barite exports.

- Cosmetics Manufacturers: In the cosmetics industry, barite is used as a filler and thickening agent in various beauty products. Manufacturers looking for high-quality ingredients may find value in sourcing barite, making them an important target customer for exporters.

- Textile Manufacturers: Textile manufacturers utilize barite in dyeing processes and as a weighting agent in fabrics. Companies in this sector may require barite to enhance the quality of their textile products, representing a potential market for barite exporters.

- Adhesive and Sealant Manufacturers: Barite is often used in the formulation of adhesives and sealants. Manufacturers in this industry seek barite to improve the performance and durability of their products, creating opportunities for barite exporters.

- Rubber and Tire Manufacturers: The rubber and tire industry uses barite as a filler to enhance the strength and durability of rubber products. Exporters can target this industry to supply barite for various applications, contributing to their growth.

- Heavy Equipment Manufacturers: Companies producing heavy equipment and machinery may require barite for various applications, including as a weighting agent in the manufacturing process. This market segment presents opportunities for barite exporters looking to diversify their customer base.

- Industrial Flooring Companies: Industrial flooring solutions often use barite in their formulations to improve durability and strength. Companies specializing in industrial flooring can be targeted for barite supplies, especially for heavy-duty applications.

- Water Treatment Companies: Water treatment facilities may use barite in the process of removing impurities from water. Companies involved in environmental remediation and water treatment represent a niche market for barite exports.

- Research and Development Institutions: Research institutions and laboratories may require barite for experimental purposes or as a raw material in scientific studies. Collaborating with these institutions can lead to unique business opportunities in the barite export business.

- Government Agencies: Government agencies involved in infrastructure development may require barite for various construction projects. Engaging with these agencies can provide a steady demand for barite supplies in public works.

- Export Agents: Export agents and intermediaries play a crucial role in facilitating barite exports. They connect exporters with potential buyers across different markets, making them valuable partners in the barite export business.

- Local Distributors: Local distributors who specialize in selling industrial materials may be interested in sourcing barite for their customers. Building relationships with these distributors can help expand market reach.

- Online Marketplaces: Online marketplaces and e-commerce platforms can serve as a channel for reaching customers in various industries. Exporters can leverage digital platforms to market and sell barite to a wider audience.

- International Traders: International trading companies that specialize in raw materials may seek barite from Nigeria and Africa for their clients in various sectors. Targeting these traders can open doors to global markets.

- Construction Material Suppliers: Suppliers of construction materials often seek high-quality fillers and additives for their products. They can be targeted as potential customers for barite, especially as construction projects grow across Nigeria and Africa.

How To Find International Buyers For Barite Export In Nigeria or Africa

- Utilize Online Marketplaces: Online marketplaces such as Alibaba, Global Sources, and TradeIndia provide a platform for exporters to connect with international buyers. By creating a professional profile and listing barite products with detailed descriptions, exporters can reach a global audience. It’s essential to optimize listings with relevant keywords and high-quality images to attract potential buyers. Engaging in online negotiations and using marketplace tools to communicate can facilitate the sales process.

- Attend Trade Shows and Expos: Participating in trade shows and expos focused on mining, minerals, and industrial materials provides opportunities to meet potential international buyers face-to-face. Events such as the Mining Indaba in South Africa or the African Mining Conference attract global industry stakeholders. By showcasing barite products and networking with industry professionals, exporters can build relationships and explore market opportunities.

- Leverage Export Promotion Agencies: Government export promotion agencies, such as the Nigerian Export Promotion Council (NEPC), offer resources and support for finding international buyers. These agencies provide information on trade missions, buyer-seller meetings, and export training programs. Utilizing their network can help exporters connect with potential buyers and navigate export regulations.

- Utilize Social Media Platforms: Social media platforms like LinkedIn, Facebook, and Instagram can be powerful tools for finding international buyers. By sharing informative content about barite and its applications, exporters can engage with industry professionals and potential clients. Joining relevant groups and forums focused on mining and minerals can further enhance visibility and networking opportunities.

- Develop a Professional Website: A well-designed, informative website acts as a digital storefront for barite exporters. Including product descriptions, specifications, and contact information is crucial for attracting international buyers. Implementing search engine optimization (SEO) strategies can improve website visibility on search engines, driving traffic and potential leads to the site.

- Join Industry Associations: Becoming a member of industry associations related to mining and minerals can provide access to valuable networks. Organizations like the African Minerals Development Centre and the International Barite Association offer platforms for collaboration and information sharing. Engaging with fellow members can lead to potential buyer referrals and partnerships.

- Network with Local Chambers of Commerce: Local chambers of commerce often have connections with international trade organizations. Engaging with these chambers can help exporters identify potential buyers and gain insights into market trends. Participating in chamber events and workshops can enhance networking opportunities.

- Engage with Importers: Researching and reaching out to importers who specialize in minerals and industrial materials is a direct approach to finding buyers. Compiling a list of potential importers and sending tailored emails or proposals can initiate conversations. Understanding the specific needs and preferences of these importers can increase the chances of successful partnerships.

- Utilize B2B Networking Platforms: Business-to-business (B2B) networking platforms like Kompass, ThomasNet, and Export Genius connect exporters with potential buyers. By listing barite products and engaging in discussions on these platforms, exporters can generate leads and establish connections with international clients.